Proper roof insulation is a crucial component of any energy-efficient home, playing a significant role in reducing heating costs and maintaining year-round comfort. As energy prices continue to rise and climate concerns grow, understanding the thermal dynamics of roof insulation materials and their impact on a building’s overall performance has become increasingly important. This comprehensive guide explores the science behind roof insulation, its effects on energy consumption, and the latest techniques for optimising insulation efficiency.

Thermal dynamics of roof insulation materials

The effectiveness of roof insulation largely depends on the thermal properties of the materials used. Different insulation types have varying abilities to resist heat flow, a property measured by the material’s R-value. The higher the R-value, the better the insulation’s performance in reducing heat transfer.

Insulation materials work by trapping tiny pockets of air or gas within their structure, which slows down the conduction of heat. Some common insulation materials include fibreglass, mineral wool, cellulose, and synthetic foam products like polyisocyanurate (PIR) and extruded polystyrene (XPS).

When selecting insulation materials, it’s essential to consider factors such as thermal conductivity, density, moisture resistance, and fire performance. Each of these properties contributes to the overall effectiveness of the insulation in regulating temperature and reducing energy costs.

Choosing the right insulation material can lead to energy savings of up to 30% in a typical residential building, significantly impacting both comfort and utility bills.

R-value optimization for Year-Round temperature control

Optimizing the R-value of roof insulation is crucial for maintaining consistent indoor temperatures throughout the year. The ideal R-value depends on factors such as local climate, building design, and energy efficiency goals. In colder regions, higher R-values are generally recommended to prevent heat loss during winter, while in warmer climates, a balance between insulation and proper ventilation is key to managing summer heat gain.

Calculating effective R-Values for common insulation types

To determine the most suitable insulation for a specific roof, it’s important to understand how to calculate effective R-values. The effective R-value takes into account not only the insulation material itself but also the entire roof assembly, including air gaps and structural elements.

For example, the effective R-value of a roof system with 6 inches of fibreglass batts (R-19) installed between rafters may be reduced by up to 20% due to thermal bridging through the wood framing. This highlights the importance of considering the entire roof assembly when planning insulation strategies.

Polyisocyanurate vs. extruded polystyrene performance analysis

Two popular synthetic foam insulation materials, polyisocyanurate (PIR) and extruded polystyrene (XPS), offer high R-values per inch of thickness. PIR typically provides an R-value of 5.6 to 6.5 per inch, while XPS offers about 5 per inch. However, the performance of these materials can vary with temperature and age.

PIR tends to perform better in warmer conditions but may lose some of its insulating properties in extremely cold temperatures. XPS, on the other hand, maintains its R-value more consistently across a wide temperature range. When choosing between these materials, consider the local climate and the specific requirements of the building.

Radiant barrier systems and their impact on heat transfer

Radiant barrier systems are an additional component that can enhance the performance of roof insulation, particularly in hot climates. These systems typically consist of a highly reflective material, such as aluminium foil, installed in the roof assembly to reflect radiant heat away from the living space.

While radiant barriers do not provide significant R-value themselves, they can reduce heat gain through the roof by up to 97% when properly installed. This can lead to lower cooling costs and improved comfort during hot summer months. However, the effectiveness of radiant barriers diminishes in cooler climates where heat gain is less of a concern.

Thermal bridging mitigation techniques in roof assemblies

Thermal bridging occurs when heat finds a path of least resistance through the building envelope, typically through structural elements with higher thermal conductivity than the surrounding insulation. In roof assemblies, common thermal bridges include rafters, trusses, and fasteners.

To mitigate thermal bridging, several techniques can be employed:

- Continuous insulation layers above or below the roof deck

- Use of thermal breaks, such as rigid foam strips between framing and sheathing

- Advanced framing techniques that reduce the amount of structural wood in the assembly

- Careful detailing around penetrations and roof-wall intersections

By addressing thermal bridging, the overall thermal performance of the roof can be significantly improved, leading to better energy efficiency and comfort.

Energy modeling: quantifying insulation’s impact on HVAC load

To truly understand the impact of roof insulation on heating costs and comfort, energy modeling tools are invaluable. These sophisticated software programs allow designers and engineers to simulate the performance of a building under various conditions, including different insulation scenarios.

Energyplus simulation for roof insulation scenarios

EnergyPlus, a widely used energy simulation program, can model the effects of different roof insulation strategies on a building’s HVAC load. By inputting detailed information about the building geometry, construction materials, occupancy patterns, and local climate data, EnergyPlus can provide accurate predictions of energy consumption and thermal comfort levels.

For example, a simulation might compare the annual energy use of a building with standard code-compliant roof insulation to one with high-performance insulation. The results could show not only the potential energy savings but also the impact on peak heating and cooling loads, which can inform decisions about HVAC system sizing.

ASHRAE 90.1 compliance and beyond: exceeding minimum standards

The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) Standard 90.1 sets minimum requirements for energy-efficient design in most buildings. However, many projects aim to exceed these standards to achieve higher levels of performance and sustainability.

Energy modeling can demonstrate compliance with ASHRAE 90.1 and quantify the benefits of going beyond the minimum requirements. For instance, increasing roof insulation levels by 20% above code requirements might result in a 5-10% reduction in annual HVAC energy use, depending on the building type and location.

Life cycle cost analysis of High-Performance roof insulation

While high-performance insulation materials may have higher upfront costs, a life cycle cost analysis (LCCA) can reveal their long-term economic benefits. LCCA takes into account not only initial installation costs but also ongoing energy savings, maintenance requirements, and the expected lifespan of the insulation.

For example, an LCCA might show that investing in premium insulation with a higher R-value could pay for itself in energy savings within 5-7 years and continue to provide benefits for the life of the building. This analysis can be crucial in making informed decisions about insulation investments.

Installation methods and their effect on insulation efficiency

The effectiveness of roof insulation is not solely determined by the material chosen; the installation method plays a crucial role in achieving optimal performance. Proper installation ensures that the insulation’s theoretical R-value is realised in practice, minimizing gaps and compression that can reduce efficiency.

Spray foam application: Closed-Cell vs. Open-Cell comparisons

Spray foam insulation has gained popularity due to its ability to create a seamless air barrier and insulation layer in one application. There are two main types of spray foam: closed-cell and open-cell, each with distinct properties and applications.

Closed-cell spray foam offers a higher R-value per inch (typically R-6 to R-7) and acts as a vapour barrier, making it suitable for areas prone to moisture issues. Open-cell foam has a lower R-value (around R-3.6 per inch) but is more permeable to water vapour and often less expensive.

When applying spray foam in roof assemblies, it’s crucial to consider factors such as:

- The desired R-value and available space

- Local climate and moisture control requirements

- The need for air sealing in addition to insulation

- Building code requirements for fire resistance and thermal barriers

Proper application technique is essential to avoid common issues such as shrinkage, off-gassing, or improper mixing ratios that can compromise the foam’s performance.

Blown-in cellulose: density considerations for optimal performance

Cellulose insulation, made from recycled paper products, is often installed as a blown-in material in attics and roof cavities. The density at which cellulose is installed significantly affects its performance and settling over time.

For optimal results, cellulose should be installed at the following densities:

- Attic floors: 1.5 to 2 pounds per cubic foot

- Enclosed cavities (e.g., cathedral ceilings): 3.5 to 4 pounds per cubic foot

Achieving the correct density requires careful calibration of the blowing equipment and expertise on the part of the installer. Insufficient density can lead to settling and reduced R-value over time, while excessive density can cause unnecessary material waste and potentially stress the building structure.

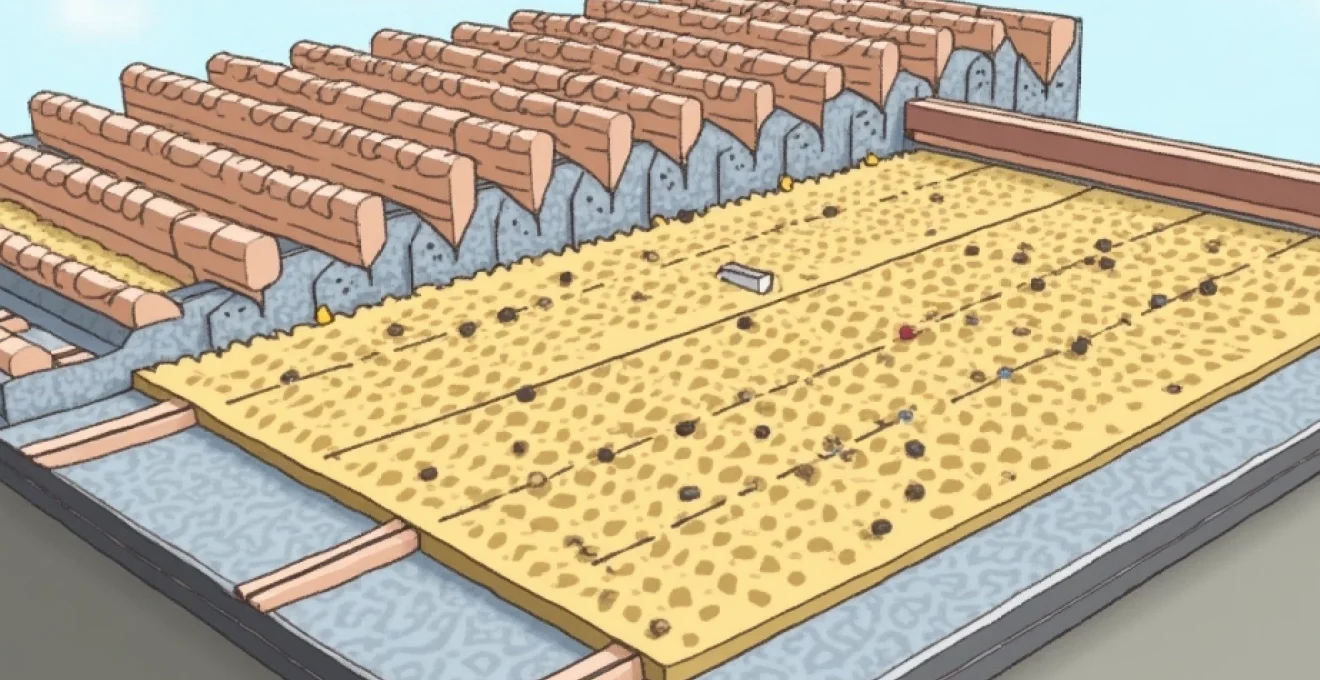

Rigid board installation: techniques for minimizing thermal gaps

Rigid insulation boards, such as polyisocyanurate or extruded polystyrene, are often used in low-slope roofing systems or as an additional layer in pitched roof assemblies. The key to maximizing their effectiveness lies in minimizing thermal gaps between boards and at the edges of the roof.

Effective installation techniques include:

- Using multiple layers with staggered joints to reduce thermal bridging

- Taping seams with specialized insulation tape to create an air barrier

- Ensuring tight fits around penetrations and at roof edges

- Using compatible adhesives or mechanical fasteners as appropriate for the roofing system

Attention to detail during installation can significantly improve the overall thermal performance of the roof assembly, reducing heat loss and improving energy efficiency.

Moisture management in insulated roof systems

Effective moisture management is critical in insulated roof systems to prevent condensation, mould growth, and degradation of building materials. A well-designed roof assembly must not only provide thermal insulation but also control the movement of water vapour to maintain a dry and healthy building envelope.

Vapor barriers: placement strategies for different climate zones

The placement of vapor barriers in roof assemblies depends largely on the local climate and the direction of vapor drive. In cold climates, where indoor spaces are typically warmer and more humid than the outdoors during winter, vapor barriers are generally placed on the warm side of the insulation (towards the interior) to prevent moisture from condensing within the roof assembly.

In hot, humid climates, the situation is often reversed, and vapor barriers may be placed on the exterior side of the insulation to prevent moisture intrusion from the outside. However, in many cases, a more nuanced approach is required, especially in mixed climates or buildings with high indoor humidity levels.

Careful consideration of vapor barrier placement is essential to prevent moisture-related issues that can compromise insulation performance and building durability.

Ventilation requirements: balancing airflow and insulation integrity

Proper ventilation is crucial in many roof assemblies to remove excess moisture and heat. In traditional attic spaces, this is typically achieved through a combination of soffit and ridge vents, creating a natural airflow that helps regulate temperature and humidity levels.

However, ventilation strategies must be carefully balanced with insulation requirements. In some cases, such as with unvented roof assemblies or cathedral ceilings, alternative approaches may be necessary. These might include:

- Using air-impermeable insulation like closed-cell spray foam

- Incorporating a ventilated air space above the insulation layer

- Employing active mechanical ventilation systems in complex roof geometries

The goal is to maintain the integrity of the insulation while providing sufficient air movement to prevent moisture accumulation.

Hygrothermal analysis using WUFI software for Long-Term performance

To ensure the long-term performance of insulated roof systems, hygrothermal analysis tools like WUFI (Wärme und Feuchte instationär) are invaluable. WUFI allows designers to model the movement of heat and moisture through building assemblies over time, taking into account factors such as material properties, climate data, and indoor conditions.

By simulating different scenarios, WUFI can help identify potential moisture problems before they occur, allowing for adjustments in the design phase. This might include:

- Optimizing insulation thickness and type

- Evaluating the need for vapor retarders or air barriers

- Assessing the drying potential of different roof assemblies

- Predicting the risk of condensation or mold growth under various conditions

Using such advanced analysis tools can lead to more resilient and efficient roof designs, ensuring that insulation performs effectively throughout the building’s lifespan.

Retrofitting existing roofs: insulation upgrade strategies

Upgrading the insulation in existing roofs presents unique challenges but can offer significant benefits in terms of energy savings and improved comfort. Retrofit strategies must consider the existing roof structure, potential moisture issues, and the practicality of different insulation options.

Energy audits and thermographic imaging for insulation assessment

Before undertaking any retrofit project, a thorough assessment of the current insulation performance is essential. Energy audits, including blower door tests and thermographic imaging, can reveal areas of heat loss and air leakage that may not be visible to the naked eye.

Thermographic cameras detect infrared radiation, allowing technicians to visualize temperature differences across roof surfaces. This can highlight:

- Areas of insufficient insulation

- Thermal bridges where heat is escaping

- Moisture intrusion that may be compromising insulation performance

Armed with this information, building owners and contractors can develop targeted retrofit strategies that address the most critical areas for improvement.

Cool roof coatings: synergies with insulation for urban heat islands

In urban environments, where the heat island effect can lead to elevated temperatures and increased cooling demands, cool roof coatings can complement insulation upgrades. These reflective coatings reduce solar heat gain by reflecting a higher percentage of incoming solar radiation.

When combined with improved insulation, cool roof coatings can:

- Reduce cooling loads by up to 15-20% in hot climates

- Extend the life of roofing materials by reducing thermal stress

- Contribute to urban heat island mitigation efforts

- Improve the overall energy performance of the building envelope

The synergy between cool roofs and insulation can lead to more significant energy savings than either strategy alone, especially in regions with high cooling demands.

Passive house principles applied to roof insulation retrofits

The Passive House standard, known for its rigorous energy efficiency requirements, offers valuable principles that can be applied to roof insulation retrofits. While achieving full Passive House certification may not be feasible for existing buildings, adopting key concepts can greatly improve performance.

Passive House principles relevant to roof insulation retrofits include:

- Super

-insulation levels approaching 12-16 inches (300-400mm) of high-performance materials

When applying these principles to roof insulation retrofits, consider:

- Adding exterior insulation above the existing roof deck to create a continuous thermal barrier

- Upgrading attic floor insulation to very high R-values (R-60 or greater)

- Implementing an airtight layer, such as a smart vapor retarder, to control air and moisture movement

- Installing high-performance skylights or roof windows to improve daylighting while maintaining thermal performance

While achieving full Passive House performance may not be feasible in all retrofit scenarios, incorporating these principles can significantly improve the energy efficiency and comfort of existing buildings. By focusing on superinsulation, airtightness, and thermal bridge reduction, roof insulation retrofits can approach Passive House levels of performance, resulting in dramatic reductions in heating and cooling costs.

Implementing Passive House principles in roof insulation retrofits can lead to energy savings of up to 75-90% compared to conventional building standards, significantly impacting both comfort and long-term operating costs.

As we continue to address the challenges of climate change and rising energy costs, the principles of Passive House design offer a proven framework for creating high-performance building envelopes. By applying these concepts to roof insulation retrofits, we can transform existing buildings into more sustainable, comfortable, and energy-efficient spaces for years to come.